First, the working principle

Signal gate valves are often used in automatic sprinkler fire protection piping systems to monitor water supply lines and to remotely indicate valve opening. By turning the hand wheel, the thread of the hand wheel and the valve stem is controlled to advance and retreat, and the valve plate linked with the valve stem is raised or lowered to achieve the purpose of opening and closing.

Second, the product introduction

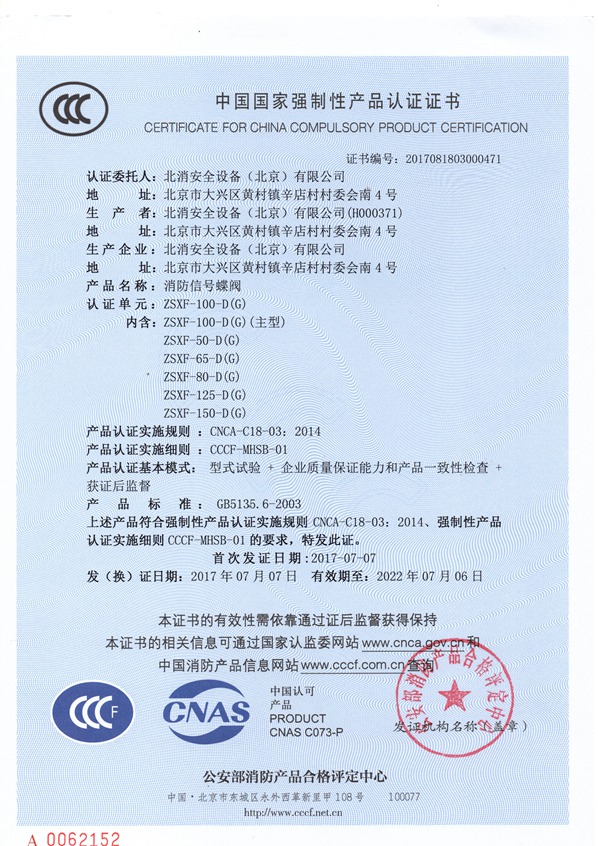

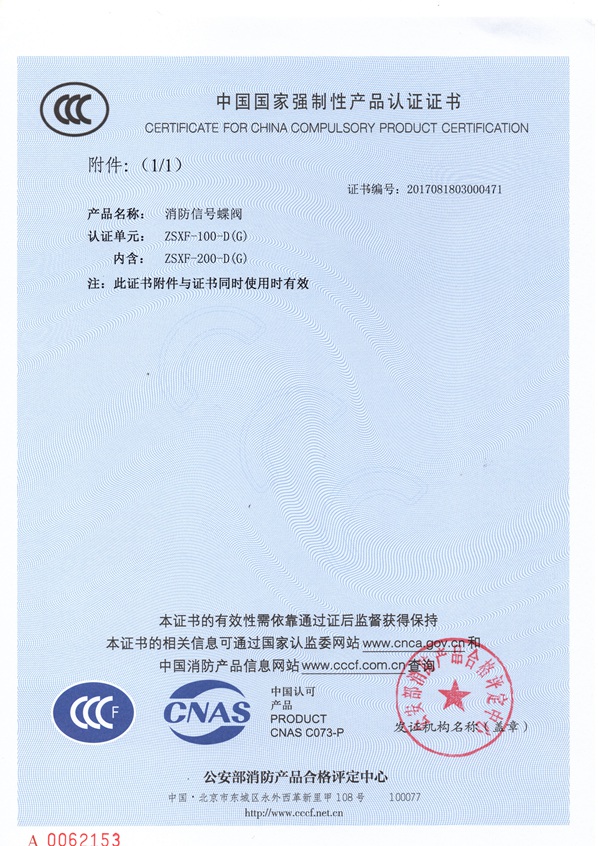

The signal gate valve body produced by our company is made of ductile iron, the valve plate is made of ductile iron, the sealing material is EPDM, and the shaft material is 45# steel chrome. The signal gate valve is equipped with a signaling device that emits an electrical signal when the valve plate is disengaged from the fully closed position. Signal gate valve production standards: "GB5135.6 automatic sprinkler system part 6: general valve."

Third, product advantages and uses

In addition to the advantages of the elastic seat sealing gate valve, the fire signal gate valve is quick and reliable to open and close, and can display the degree of valve opening more intuitively, so that the opening degree of the valve can be judged at a remote place, and corresponding measures are taken in time. The fire signal gate valve is installed at both ends of the alarm valve group or at the inlet of each branch of the system. When the alarm valve group or network is repaired, turn it off. The signal gate valve is equipped with a signal device that can emit an electrical signal to indicate the state of the valve plate.

Fourth, product technical parameters installation size

Applicable medium: water, oil, gas, etc.

Adapt to temperature: 0 ~ 80 ° C

Signal power supply: DC24V, 3A

Nominal operating pressure: 1.6MPa

Test standard: GB13927 AP1598

Figure 1 Schematic diagram of the signal gate valve

Sixth, installation and maintenance instructions

a. There should be a certain space around the signal gate valve for easy installation and maintenance operations;

b. During the transportation and installation process, the signal gate valve should avoid violent collision as much as possible to prevent the sealing surface and micro switch from being damaged, which affects its sealing performance and the normal operation of the electrical signal system;

c. Do not disassemble and adjust the signal gate valve before and after installation;

d. After the signal gate valve is installed, before the pipeline is sealed and tested, the valve plate should be completely opened to flush the inner cavity of the pipe. Otherwise, the valve plate may not be closed tightly. The closed or open state should be locked.