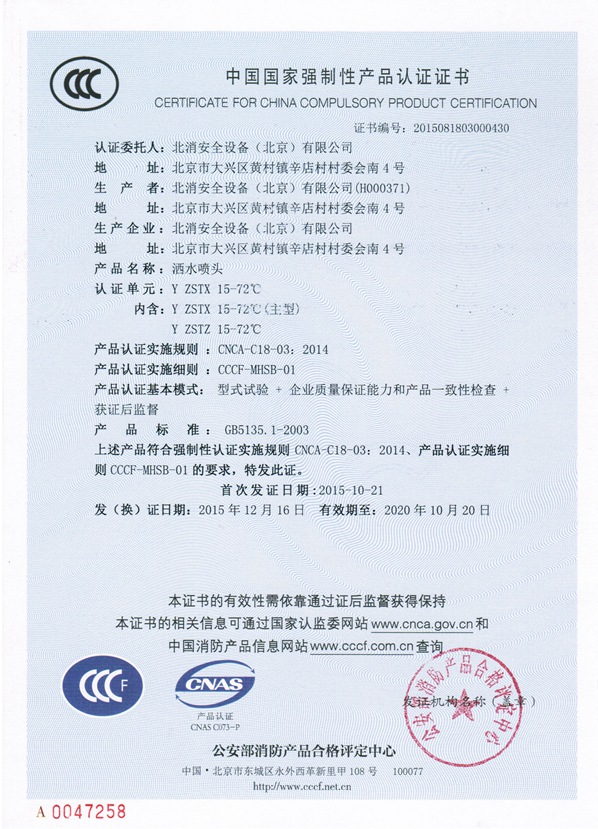

First, use:

ZST series fusible alloy sprinklers have the same technical performance and functional safety as other glass ball sprinklers. Only the temperature-sensing mechanism is safer and the performance is more excellent and reliable. It and other components such as wet alarm valve, water flow indicator, fire pressure switch, fire pipe network and other wet sprinkler systems. It is the most important component in the system, it is used to detect fire, start system and sprinkler. It uses a fusible alloy instead of a glass ball as a temperature sensing element, and its bearing strength is more than twice that of a glass ball. Its low temperature resistance is better than that of a glass ball, and it is mainly used in places where it is easy to collide.

Second, the characteristics:

ZST type fusible alloy sprinkler is assembled from copper alloy frame, fusible element, ball seat, seal, splashing disc, etc. It has reasonable design and beautiful appearance.

1. The nozzle frame is formed by H59 copper rods, which are made of high-strength, corrosion-resistant and polished.

2, the temperature sensing element is made of fusible alloy material, the performance is stable, the operating temperature is accurate, and the fire can be extinguished in time.

3. The temperature-sensing mechanism has a higher safety factor, and the probability of being hit and crashed is smaller than that of the glass ball nozzle.

Third, the main technical parameters:

1. Nominal diameter: 15mm, interface thread: R1/2. Flow characteristic coefficient: K=80±4.

2, rated working pressure: 1.2MPa, factory seal test pressure: 3.2MPa.100% detection.

3. Response time coefficient: RTI ≤ 80.

4, the fusible component nominal operating temperature: 72 ° C

5, the highest ambient temperature: 42 ° C

6, installation form: upright type: upright vertical installation; drooping type: sagging vertical installation.

Fourth, storage, installation, use and maintenance precautions:

1. Sprinklers should be stored in a dry environment at -15 °C ~ 40 °C.

2. It is recommended to use PTFE sealing tape when installing the nozzle and the threaded joint of the pipe fittings. The pipe fittings should be products that meet the national standards.

3. When installing the nozzle, use the 22-inch wrench of the (22X24) wrench and pay attention to the correct use, as shown below. The nozzle tightening force distance is 10-20N.m, and it is strictly prohibited to exceed 30N.m.

4, the nozzle should be kept clean, spray paint, paint, etc. are strictly prohibited.

5. The nozzles to be installed should be stored in the foam protection box provided by the factory. The construction personnel should not use other containers at will: such as helmets and paint buckets.

6, pick and place nozzles are not allowed to use parabolic, grasping, dumping, etc., must be lightly handled, lightly placed, glass balls are strictly prohibited collision. The company is not responsible for the leakage caused by the damage of the nozzle frame and the looseness of the fusible components due to irregular operation or installation.